Utility services

Tooling service for molds

We offer fast and reliable tooling service for aluminum die casting tools, adapted for Swedish foundries that require high precision and short lead times.

Preventive tool service for increased tool life

Regular tool service is essential to keep production running without unnecessary downtime. We help foundries throughout Sweden to extend the life of their molds through qualified maintenance, adjustment and component replacement. The goal is to ensure that each tool performs optimally year after year.

Our tooling service is tailored to the customer's equipment, production volumes and potential operational issues. By identifying wear at an early stage, we can prevent breakdowns and reduce downtime. All work is documented and follows established quality procedures according to our certifications. The result is a more stable manufacturing process and longer intervals between major interventions.

Repairs, improvements and technical support

We accept molds for both simple operations and extensive renovations. Cracks, misalignments, worn mating surfaces or damage after long operation are things we deal with daily. In many cases, it is also possible to upgrade the tool at the same time, for example by improving cooling, material selection or design solution. In cases where there is an opportunity to increase performance or reduce cycle time, we suggest it.

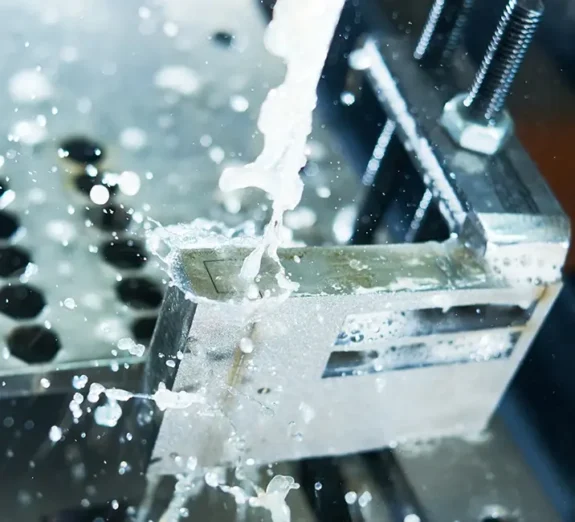

All tool service takes place in our own workshop in Värnamo. There we have access to our entire machine park, including multi-axis milling machines, wire EDM machines and surface grinders. This means that we can quickly fix even complicated faults without having to send the tools on. By gathering design, service and manufacturing under the same roof, we can maintain a high level of service and short response times - something that is difficult to achieve if the tools are manufactured abroad.

This includes

- Troubleshooting and functional testing

- Wear analysis of component parts

- Replacement or renovation of inserts

- Alignment of mating surfaces and tolerances

- Installation of new cooling ducts

- Documentation and functional protocols

- Simulation of casting process in cooperation with consultant

Tool services from the new generation of toolmakers.

Having a tooling service partner who understands the big picture makes a big difference. At Formteknik Värnamo, we are not just toolmakers - we are part of your production, with deep technical expertise and understanding of real production flows. When a mold is to be serviced, we make sure to not only fix the symptoms, but also analyze why the problems occurred.

Our aim is to ensure that your tools perform as well after service as when they were new. We offer both one-off and ongoing service contracts for customers who want to minimize the risks of unplanned downtime. In an industry where many still rely on imports without local support, we stand for availability, quick feedback and a long-term commitment.