Lego manufacturing

Lego manufacturing in aluminum

Lego manufacturing with a technical focus, modern machines and full control from first drawing to finished component.

Lego manufacturing for industries that demand more

Formteknik Värnamo offers contract manufacturing of large aluminum parts and prototypes for companies that place high demands on precision, flexibility and delivery reliability. We work with both short series and single components where no solution is standard. By combining our experience of molds with our modern machinery, we can produce parts that require precise geometry, tight tolerances and good surface finish. Subcontracting can also be carried out in other materials, such as steel, aluminum and special alloys depending on the application and requirements.

Most assignments come from foundries and designers who need a flexible partner for subcontracting outside their own processes. This may involve quickly producing a prototype, testing a new design or producing parts that are not suitable for automated mass production. All projects are handled in our own workshop in Värnamo, giving us full control over quality, delivery times and technical adjustments along the way.

From idea to finished part with subcontracting

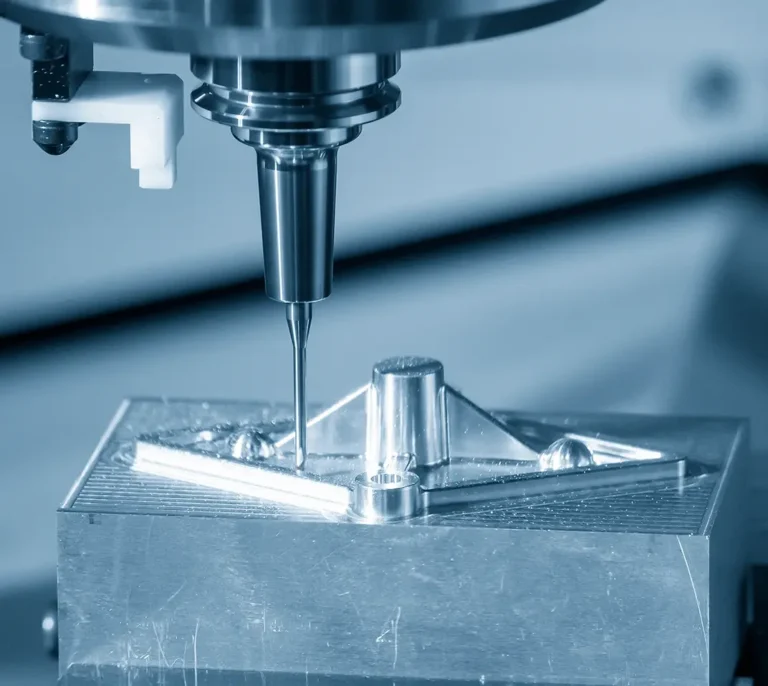

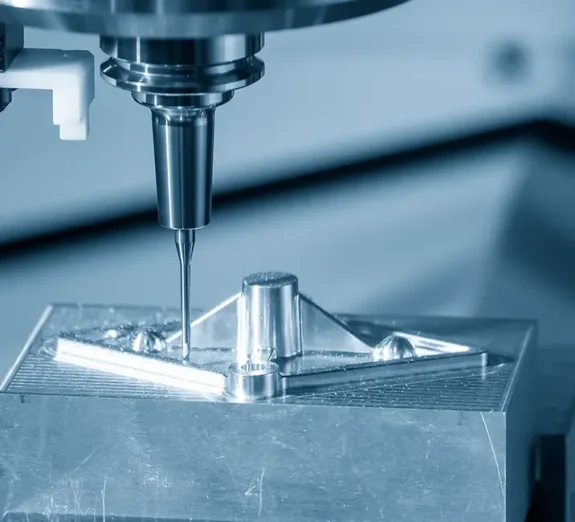

Lego manufacturing with us often starts with a drawing or a 3D model, which we analyze together with the customer based on material selection, tolerances and production volume. From there, we develop a machining plan that combines the right machine, the right fixture and the right clamping for each unique part. Our machinery includes GROB G750, G550, Mikron VC1000, wire EDM, submerged arc EDM and surface grinding - enabling us to machine both large and complex components with great accuracy.

It's not uncommon for the workpieces we handle to weigh several hundred kilograms or have features that require machining from several directions. That's why subcontracting with us is closely linked to what we do best - technical problem solving, close communication and a practical understanding of what works in real-world operations. All manufacturing is done locally, which not only shortens lead times but also allows for quick adjustments or building on existing parts. At a time when much subcontracting is sourced from abroad, local proximity becomes a crucial advantage.

Example of subcontracting

- Larger aluminum components for industrial use

- Prototypes and development parts for verification and testing

- Precision parts with shape and tolerance requirements

- Complicated geometries in low to medium volume

- Machining with milling, sparking and grinding

- Complete solutions from drawing to finished product

Lego manufacturing with new generation toolmakers.

Finding a contract manufacturing partner that both understands the technology and has the resources to deliver requires more than just good machinery. It is about experience, holistic understanding and a willingness to solve tasks that do not always fit into the standard flow. At Formteknik Värnamo, this knowledge is combined with high capacity, great commitment and a working method where the customer's process controls the solution.

We are new generation toolmakers and contract manufacturers focusing on industrial customers throughout Sweden. By working closely with designers, buyers and production teams, we can adapt each assignment to real needs. We do not only produce according to drawings, but we optimize for durability, function and manufacturability right from the start.