Molds and dies

Molds for die-casting

We manufacture advanced molds for die casting with full control over the entire process, from drawing to finished product. Our customers are Swedish foundries that value high precision, fast lead times and local availability.

Molds that meet industry requirements

Formteknik Värnamo is the new generation of toolmakers, specializing in complete die-casting tools for aluminum die-casting. What we deliver is used to manufacture components for end customers such as Volvo, Scania, ABB and Atlas Copco. Regardless of whether they are vehicle parts or industrial details, the requirements are the same - the tools must be dimensionally stable, durable and adapted for series production in tough environments.

The whole process starts with a 3D model of the finished component, produced by the end customer. The model is sent to the foundry, which in turn contacts us. We then take over responsibility for the design of the mold, make technical adjustments where necessary and manufacture the mold in our own workshop. We handle every step in-house, which makes it possible to produce unique solutions with short lead times and high control.

Advanced solutions with full control

What sets our tools apart is the combination of flexibility and technical detail. Many of the tools we produce are fully customized and consist of hundreds of parts. The tools are manufactured to withstand high temperatures, high pressure and long production runs without losing shape or function. The maximum size is approximately 1500 mm x 1000 mm, but we customize the tool design exactly to your product and manufacturing method.

By working with both design and manufacturing in the same house, we minimize the risk of errors, save time and can quickly make adjustments if conditions change. This creates security from the first offer to the final delivery.

Molds we manufacture

- Die-casting tools for aluminum parts

- Prototyping tools for short runs or test series

- Customized cores and interchangeable inserts

- Beard/clip tools for the casting cones

- Other types of molds according to customer requirements

- Fixtures and fittings for production lines

Modern machinery, experienced designers, short lead times.

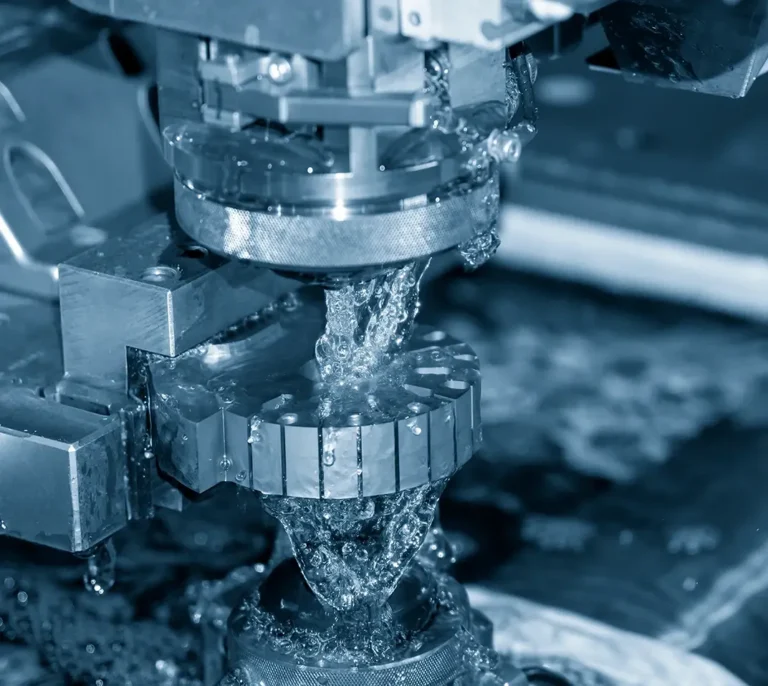

Our production takes place in our own facility in Värnamo with full equipment for precision machining. The machinery includes GROB G750 and G550, two five-axis milling machines that handle large workpieces and run virtually around the clock. We also have wire EDM, plunge EDM and surface grinding capabilities, enabling machining of complex geometry, tight tolerances and advanced surface finishes.

By bringing all manufacturing in-house, we ensure quality, eliminate lead times and can adapt quickly to changes. Designers and production work closely together, minimizing errors and optimizing results.

We produce around thirty to fifty tools per year. Each project requires a high level of technical expertise and close interaction between design, materials and machining. Today there are few Swedish toolmakers with that capacity. This makes our expertise particularly in demand, especially thanks to the possibility of local service and support.