Formteknik Värnamo AB

new generation of toolmakers.

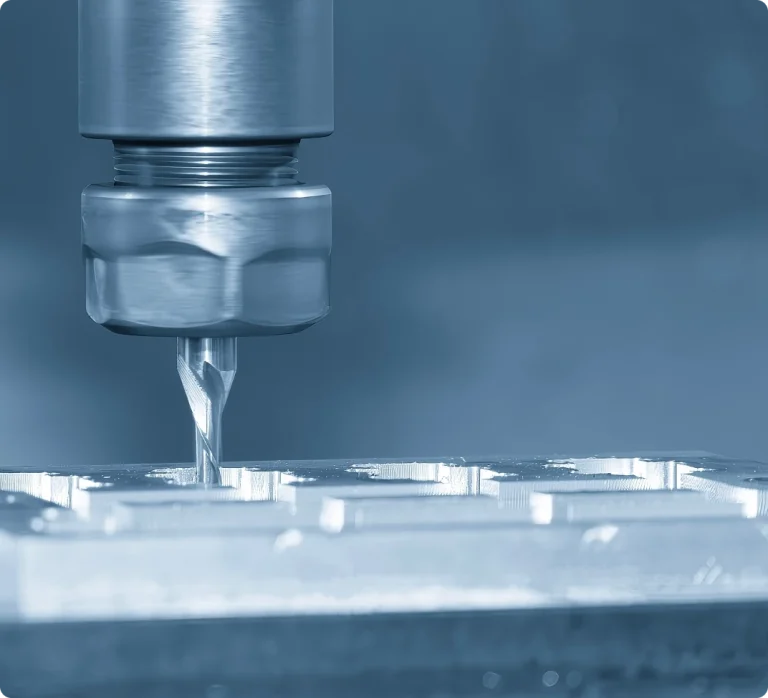

Design and manufacture of molds.

Dies for die-casting of aluminum parts

Formteknik Värnamo specializes in die-casting tools for die-casting. We develop customized solutions in aluminum, from idea to finished product. Our customers are Swedish foundries, which in turn supply companies such as Volvo, Scania, ABB and Atlas Copco. We manufacture one-off prototypes and tools for series production. Every detail is created in our own workshop.

As toolmakers, we have a clear mission: to deliver durable molds with precise fit and technically smart solutions. We work closely with the customer's designer or production manager and adapt the tool to both material flow, cooling needs and the geometry of the final component. Our machinery and experience enable us to handle complex assignments with high tolerance requirements and tight deadlines. Each mold is unique and built to perform.

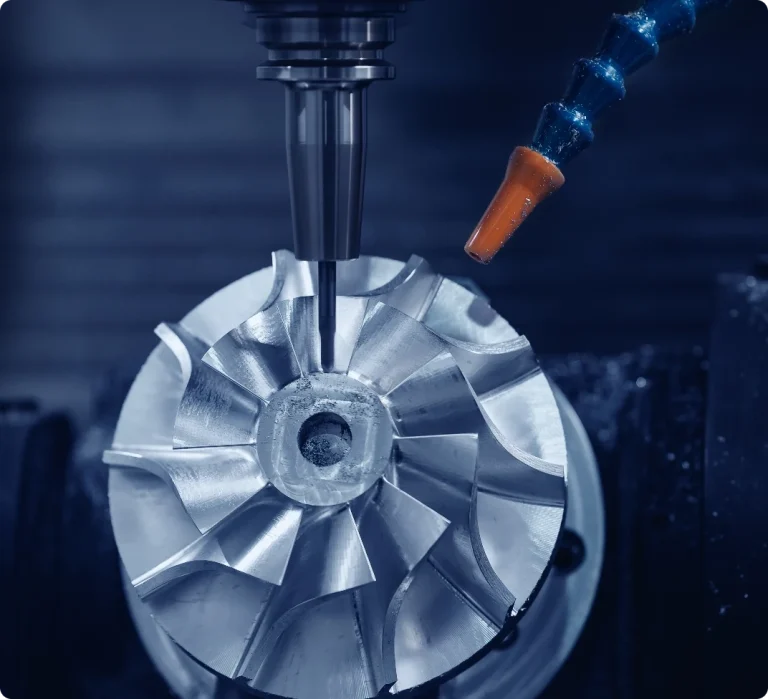

From 3D model to finished tool

At Formteknik Värnamo AB, the entire process is handled internally. Once the end customer has produced a 3D model, it is sent to the foundry, which contacts us. We take responsibility for design, machining and assembly and ensure that every detail is optimized for production. Working closely with our customers, we adjust cores, inserts and cooling channels to make the tool perform as efficiently as possible.

As toolmakers, we are used to working with short lead times and high demands on repeatability. We produce between thirty and fifty molds per year, with each mold consisting of hundreds of parts. By doing everything in our workshop, you avoid middlemen, logistics problems and misunderstandings. The result is a tool that works immediately and lasts over time.

Toolmaker since 2017

Our modern workshop in Värnamo has both five-axis milling machines, spark machines, grinding and measuring equipment. Here we manufacture all our mold tools, Lego parts and other types of mold tools where the customer provides 3D substrates on tools, such as blow molding and injection molding tools (plastic). We also offer a complete tooling service, which means that we not only build new tools, but also service, adjust and improve existing tools. In this way, we help our customers to extend the life of their tools and avoid unnecessary production stops.

Our capabilities range from prototypes to recurrent series production. With both design and manufacturing in-house, we can quickly solve technical challenges without losing momentum. As a toolmaker, we look at the entire tool lifecycle, from design to maintenance, and offer technical support throughout the journey.